Painted Engine Cowling Fitted and Installed

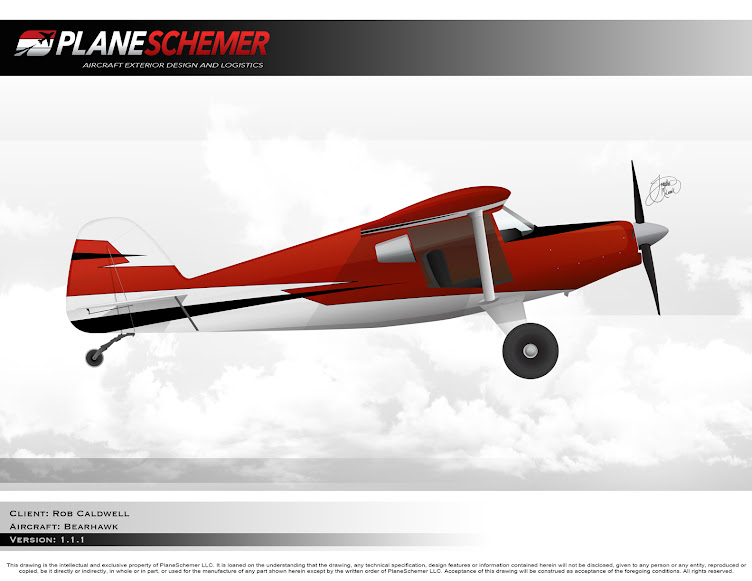

Welcome to a Builders Blog of my Bearhawk 4 Place.

Build date started: June 1, 2018.

❗️Scroll to the bottom to start at the beginning of the build❗️

Click HERE to return to the beginning of this Bearhawk Builder blog.

Friday, July 24, 2020

Thursday, July 16, 2020

Installing the Windscreen / Windscreen Fairing (Challenges)

Whoops! I trimmed the windscreen too short!

The Bearhawk 4 Place uses the Cessna 170 windscreen. Only slight trimming is need to fit the windscreen to the boot cowl. My trimming was not slight. The fix is to enlarge the windscreen fairing and fabricate a piece coving piece for the inside of the windscreen.

These pictures tell the story...

Fuel Lines ~ Firewall Forward

The firewall forward installation of the fuel lines was very straight forward. No issues. I optimized the routing by securing the lines to the engine case/sump with cushioned high temp adele clamps.

Routing from the firewall goes like this:

- Port side lower bulkhead fitting to mechanical (engine driven) fuel pump

- Mechanical fuel pump to forward facing fuel controller

- Fuel controller (metered fuel) to fuel flow transducer (top of the engine case)

- Fuel flow transducer to fuel flow divider (spider)

The fuel lines I selected are not the typical fire sleeved lines from most aviation supply houses. These lines are from TS Flightlines. Tom Swearingen is the owner and takes great care in consulting with the home builder before assembling the lines. Tom has purposely designed a better fuel line that is braided in stainless steel and covered (integrated) with teflon. Just one example of why his lines are superior... Standard lines are rated to 1,000psi. TS FLightlines are rated to 3,000psi.

SPECS....

TS Flightlines Integrated Teflon Firesleeve Fuel Lines

NEW Integrated Teflon Firesleeve

|

Standard Teflon Firesleeve

(Stratoflex 101)

| |

Conductive Teflon Liner

|

.030 Wall

|

.020 Wall

|

304 Stainless Braid

|

.006 Wire

|

.002 Wire

|

Working Pressure

|

3000 PSI

|

1000 PSI

|

Temperature Rating

|

-76*/+500*

|

-65*/+450*

|

High Temp Silicone Outer Cover

|

*.060 - .090 Thick

|

AS1072 Firesleeve

|

SPECS:

· Proprietary Design Based on MIL SPECS

· -3 through -8

· Made from 304 Stainless Bar Stock

· Meets ASTM specifications with both MIL and Inspection Reports

· CNC Machined

· CNC Mandrel Bends

· Increased ID past the normal ID average of Stratoflex, Aeroquip, Smiths Titeflex, Teleflex Aero for slightly increased flow.

· Mandrel Bends maintain a consistent bend margin

· OD of the body is not increased to achieve a consistent ID

· Uses a certified nut (Preparing for FAA certification)

· Proprietary stainless-steel crimp collars

· Tested to 7500 PSI

(I am not getting paid, just impressed with the product...)

Wednesday, July 15, 2020

Installing the Hartzell Trailblazer 84" Propeller

I am using the Hartzell 83" Trailblazer composite propellor. This was tested by Mark Goldberg of the Bearhawk factory (AviPro Aircraft). Everyone I spoke that has flown behind this prop LOVES it! Very lightweight and exceptional performance.

Hanging the prop is fairly straight forward. Hartzell technical service department was very helpful. I confirmed a few things with them from the manual. Prop governor installation and set up, prop hub orientation, safety wiring, etc. The manual tightening the prop hub to 40 ft lbs each bolt. There is a bolting sequence to be followed. You can't do it without a propellor wrench. Hartzell sells propellor wrenches, but the Ultimate Propellor Wrench works best! https://antisplataero.com/products/ultimate-propeller-wrench

Sunday, July 5, 2020

Subscribe to:

Posts (Atom)